Written by Dr. Julian Conejo

This article describes how to simplify polylines with a large number of vertices in AutoCAD. In the example below, the object on the right contains a large number of vertices, while the one on the left has fewer while maintaining the same shape. Currently, there is no dedicated command in AutoCAD or AutoCAD LT to simplify such complex polylines. On AutoCAD Map 3D and Civil 3D, a dedicated. Simplify 3D printing with Ultimaker Cura 4.0. Download Ultimaker Cura 4.0 today and enjoy a brand-new user interface designed to simplify 3D print preparation – whether you’re a beginner or an expert. This release adds integration with Ultimaker Cloud, offering you advanced cloud-based tools to support your 3D printing workflow. DMG MORI USA - CNC machine tools for all cutting machining applications. 5-Axis Excellence. 5-Axis CHAMPION – JOIN THE WINNING TEAM. World Premiere 2021. CLX 450 TC: Future-proof entry in 6-sided complete machining. TECHNOLOGY EXCELLENCE 01-2021. The new TECHNOLOGY EXCELLENCE MAGAZINE Issue 01-2021. The new Terminator 2 3D is targeting a worldwide release in 2016, but a key target market is understood to be China, where the conversion will make its global premiere courtesy of DMG’s China.

With the advances on intraoral scanning, CAD/CAM (Computer Aided Design/ Computer Aided Manufacturing) technologies and digital implantology, the need for a predictable and user-friendly

3D printing system has become a necessity for clinicians and dental technicians for completion of a true digital workflow.

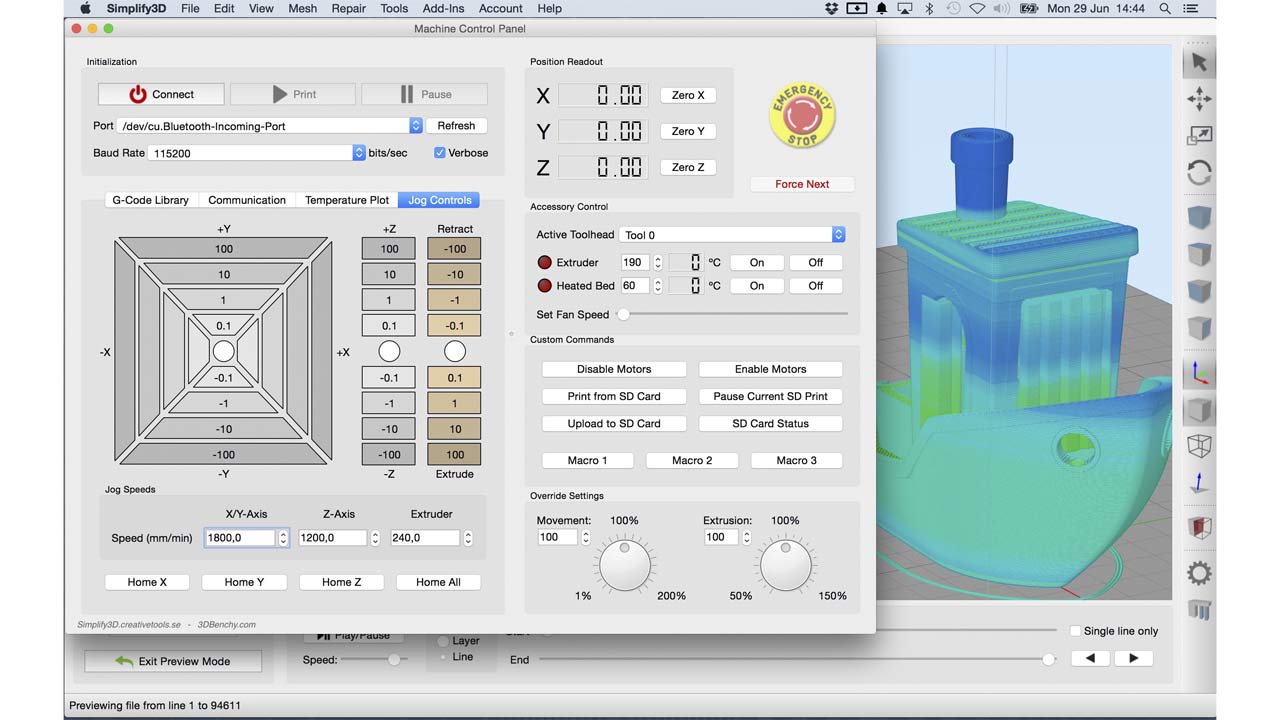

DMG’s newly released integrated 3D printing solution offers this user-friendly and simplified solution, for a seamless integration of the digital workflow. The DMG digital system includes a

validated software-supported, reproduction technology process accepting all standard .STL files. The 3Demax digital printer, 3Dewash and 3Decure units communicate via internet. By scanning the RFID code on all LuxaPrint material bottles, optimal process reliability can be obtained. (Image 1)

The LuxaPrint family of materials for 3D printing provides confidence in choosing high-quality resins for precision and accuracy of 3D printed dental devices with a wide range of applications.

All LuxaPrint materials may be used with the following printers: DMG 3Demax, Straumann P20+ & P10+ capsule and Rapidshape D30, D20+, D20+ cartridge and D10+ units.

DMG LuxaPrint resins provide clinicians and dental technicians 6 different resins, with 3 additional resins coming late 2021.

Naruto to boruto shinobi striker crossplay pc ps4. LuxaPrint Model, for elaboration of high precision models. (Image 2-3)

LuxaPrint Gingiva, for optimal elastic and high tear resistant gingival masks.

LuxaPrintCast, allowing easy fabrication of residue-free and easy-burn casting of copings and frameworks.

Simplify 3d Getting Started

LuxaPrintOrtho and Luxa Print Ortho Plus (coming soon), covering the broad-spectrum of clinical needs for the production of surgical guides, night guard and splints with clear transparency

even after sterilization. (Image 4-5)

LuxaPrintOrtho Flex, a biocompatible material for flexible soft splints for bleaching, and indirect bonding trays.

Simplify3d Dmg

LuxaPrintTray, supporting prosthetic digital workflows need for custom trays.

LuxaPrintCrown (coming soon), for 3D printing of semi-permanent crowns and bridges.

LuxaPrintBase (coming soon), for long-term stability of denture bases.

DMG will continue to simplify their user-friendly platform with the introduction of an intuitive cloud-based design software late, 2021. DMG’s DentaMile connect software will facilitate the

integration of 3D printing workflows into dental clinics and laboratories for a shortened learning curve allowing rapid organization, design, communication and printing with predetermined

parameters for each material. (Image 6)

When all variables have been considered, a smooth integration of the LuxaPrint family of materials into a user-friendly, comprehensive software and robust hardware, predictable clinical and laboratory solutions are rapidly obtained. DMG’s new 3D printing materials offer an endless number of possibilities for clinical implementation and benefit of patients worldwide. As additive production of provisional and semi-permanent crowns and bridges grow, the need for a reliable 3D printing solution is extremely important and will provide a smooth transition for clinicians and dental technicians into modern dentistry.

Exclusive DMG MORI technology cycles are effective assistants for shop floor programming and the simplest way to boost productivity, enhance safety and expand machine capability. They offer a clear program structure, intuitive operation and enable up to 60 % faster programming. In addition, they help minimize errors as well as allowing the internal transfer of complex technology know-how.

Outstanding customer benefits mean DMG MORI’s exclusive technology cycles have been writing their own digital success story for years. Their record in the field of integrated technologies is especially impressive: users trust in the exclusive technology cycles on more than 95 % of all turn & mill universal turning centers in the CTX TC series.

“Far more important for us, however, is the added value for and appreciation from our customers,” stresses Dr. Edmond Bassett as Head of Technology Management at GILDEMEISTER Drehmaschinen GmbH. He takes the MPC technology cycle, a version sold over 100 times a month and thus one of the most successful technology cycles, to illustrate the high degree of acceptance among customers. MPC stands for Machine Protection Control which, thanks to its integrated acceleration sensor, increases process safety, enables spindle bearing diagnostics and prevents expensive damage caused by collisions.

“Complex production processes that were reserved for special machines in the past now count among our powerful drivers of innovation,” says Dr. Edmond Bassett as Head of Technology Management at GILDEMEISTER Drehmaschinen GmbH.

“Intensified technology integration adds a whole new dimension to the term complete machining,” he stresses. DMG MORI gearSKIVING is just such an example. This enables the production of top quality gears through the input of clearly structured programs.

Simplify3d 4.1.2 Dmg

The exclusive portfolio currently includes 30 DMG MORI technology cycles, with two more to follow in time for the AMB. Dr. Bassett refers expressly to the new “crownHOBBING” cycle for the production of demanding Hirth couplings: “This enables users of our turn & mill centers to generate the programs they need virtually at the press of a button. The cycle handles the required tooth path calculations and the settings for the axis movements,” he concludes.